In construction, civil engineering and landscaping, digging is essential for projects of all sizes ranging from skyscrapers to utility and irrigation installations. This guide dives into the details of excavation vs trenching, empowering you with a comprehensive understanding of both subjects.

Definition – Excavation vs Trenching

Excavation and trenching are both construction techniques used to dig and create voids in the ground for various purposes. While they might seem similar, they have distinct characteristics and applications.

What is excavation?

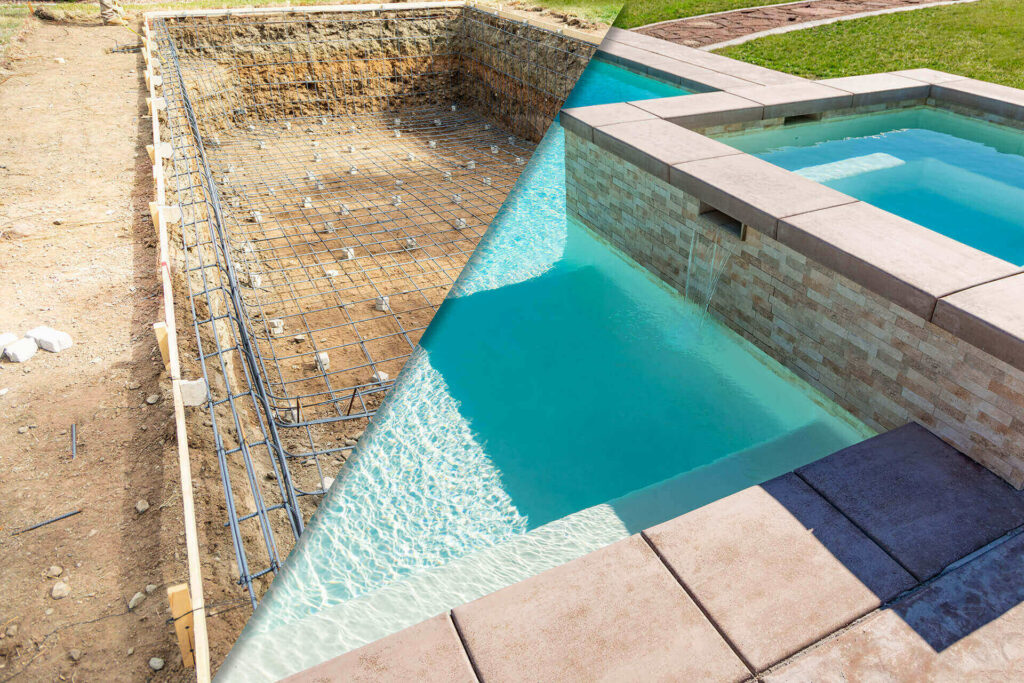

Excavation involves removing earth, rock, or other materials to create spaces for purposes such as building foundations, basements, reservoirs, or archaeological sites. The scale can range from small projects, like trenches for utility lines, to massive undertakings, such as skyscraper foundations. Heavy machinery, including excavators, bulldozers, and backhoes, facilitate these tasks due to the volume of material moved.

What is Trenching?

Trenching is a specialized excavation method that forms narrow, deep channels in the ground, typically deeper than they are wide. These trenches serve purposes such as laying utility lines, installing drainage systems, or burying cables. Their design ensures utility lines or pipes remain protected and separated from the surface. Unlike broader excavations, trenches demand precision with careful attention to depth, width, and surrounding materials for stability and safety.

Techniques – Excavation vs Trenching

Even though both involve digging, how they are done could be very different. Let’s delve into the methods and techniques used in excavation and trenching:

Excavation Techniques

Open-Cut Excavation: This is the most common method, involving the removal of soil and rock from a designated area using heavy machinery like excavators, backhoes, and bulldozers. It’s used for various purposes, including creating foundations, basements, and large-scale earthmoving.

Top-Down Construction: This method is often used in urban areas where space is limited. It involves excavating the lower levels of a construction site while simultaneously constructing the upper levels. This reduces the need for extensive lateral space for spoil piles.

Step Trenching: Commonly used for slopes or hillsides, step trenching involves creating a series of steps or terraces in the ground to provide stability during excavation. This method helps prevent landslides and erosion.

Benching: Benching is used in open-pit mining and road construction. It involves creating a series of horizontal steps, or benches, within the excavation area. Each bench provides a safe working platform for machinery and workers. It’s similar to step trenching, the differences are the width of the steps and scale.

Trenching Techniques

Open-Cut Trenching: Similar to open-cut excavation, this method involves digging a narrow, deep trench using heavy machinery. It’s primarily used for laying utility lines and cables. For smaller jobs like irrigation, it can be done by hand with basic non-powered tools, or smaller machines such as a trencher or even an edger.

Sloped Trenching: When soil conditions permit, the sides of the trench can be sloped to prevent collapses. This is common in softer soils and requires more space alongside the trench.

Box Trenching: Used in urban areas with limited space, box trenching involves excavating a trench and then using temporary retaining structures (shoring) to support the trench walls and prevent collapses. This is very important for trenching safety.

Horizontal Directional Drilling (HDD): For installing utilities without disrupting the surface, HDD involves drilling a tunnel horizontally underground and then threading utility lines through it. This is useful for crossings beneath roads, rivers, and other obstacles.

Trenchless Techniques: These methods avoid open excavation and include techniques like pipe jacking and micro tunnelling. They’re employed for utility installation in areas where minimal surface disruption is desired.

Equipment – Excavation vs Trenching

Equipment is crucial in excavation and trenching. For excavation, heavy machinery like excavators and backhoes handle various tasks, while bulldozers and loaders manage materials. Trenchers and hydraulic hammers are essential for narrow, deep channels and rock surfaces. Trenching tools focus on precise trench creation, using trenchers and attachments for larger equipment. Hand tools like shovels, picks, trench boxes, and shoring systems work for smaller tasks. Pipe lasers, levels, and cable locators aid accuracy. Trenching stands out with its specialized tools for narrow channels, while safety equipment is common to both processes.

Key Factors that Influence the Cost

The financial analysis of excavation and trench projects reveals distinct cost dynamics, each shaped by a range of factors. This comparative exploration sheds light on how these fundamental groundwork techniques differ in terms of expenses.

| Factor | Excavation | Trenching |

| Project scale & complexity | Larger excavations entail increased material movement and complexity, contributing to higher costs. | Trench projects, often more focused, may have lower costs for smaller-scale endeavors. |

| Soil characteristics | Challenging soils like rock or dense materials may require specialized equipment and labor, elevating expenses. | Soil conditions are pivotal; soft soils might lead to lower costs in trenching due to easier excavation. |

| Equipment & labor | Heavy machinery costs for equipment like excavators and bulldozers can influence expenses. Skilled operators add to labor costs. | Trenchers are often the primary equipment, potentially leading to more focused equipment costs. Labor costs can be influenced by the precision needed in narrow trenching. |

| Project duration | Larger excavations may extend project timelines, thereby increasing labor and equipment rental costs. | Trench projects’ quicker completion can lead to lower overall expenses. |

| Site accessibility & location | Remote sites can increase transportation and logistical costs. | Accessibility impacts both methods but may be more critical in excavation projects. |

| Soil removal & backfill | Usually higher due to project size. | Usually lower comparatively, but depends on trench depth. |

| Unforeseen challenges | Unexpected obstacles like encountering utilities can incur additional costs. | While trenching is focused, unforeseen utility conflicts can still impact costs. |

| Regulatory compliance | Permit expenses and adherence to regulations contribute to overall project costs. | Permit expenses and adherence to regulations contribute to overall project costs. |

Key Factors that Affect the Timeline

Excavation and trenching durations vary based on size, complexity, soil, and more. Small tasks like foundations take days to weeks; mediums like basements, weeks to months; larges like mining, months to years. Trenching differs: small lines, hours to a day; mediums like drainage, days to weeks; larges like infrastructure, weeks to months. Unexpected issues, weather, planning, and execution impact completion time.

Applications – Excavation vs Trenching

Applications of Excavations

Creating Large Spaces: If your project requires creating substantial depressions or voids in the ground, such as for building foundations, basements, or large-scale earthmoving, excavation is often the preferred choice.

Mining and Quarrying: When extracting minerals, ores, or valuable materials from the ground, excavation is the method of choice due to the large quantities of material involved.

Land Grading: If the objective is to reshape the terrain, level the ground, or create contours, excavation is a suitable method to achieve these changes on a broader scale.

Archaeological Research: For uncovering artifacts and historical information buried beneath the surface, excavation is the technique employed by archaeologists.

Applications of Trenching

Installing Utilities: Trenching is commonly chosen when the primary objective is to install utility lines such as water pipes, sewer pipes, gas lines, electrical cables, or communication lines.

Creating Linear Structures: If the project involves creating linear structures like drainage systems, culverts, or tunnels, trenching is more suitable due to its ability to create narrow, focused channels.

Limited Surface Disruption: When minimizing disruption to the surface is a priority, trenching provides a solution by focusing the excavation in a linear manner, reducing the area affected.

Fiber Optic and Cable Installation: Trenching is often used for laying fiber optic cables and communication lines, ensuring organized and protected routing of these sensitive cables.

Summary

While trenching is a type of excavation, they’re not quite the same. Each requires its own set of equipment, techniques, and safety measures, especially when depth and accuracy are paramount. It’s important to hire an excavation contractor with the right qualifications and experience that match the project needs to ensure success and safety. If you have any questions or needs at all related to excavating, you can get in touch with us by clicking the button below.